Build a Career in Industrial Manufacturing in Washington

Introduction to Industrial Manufacturing Training

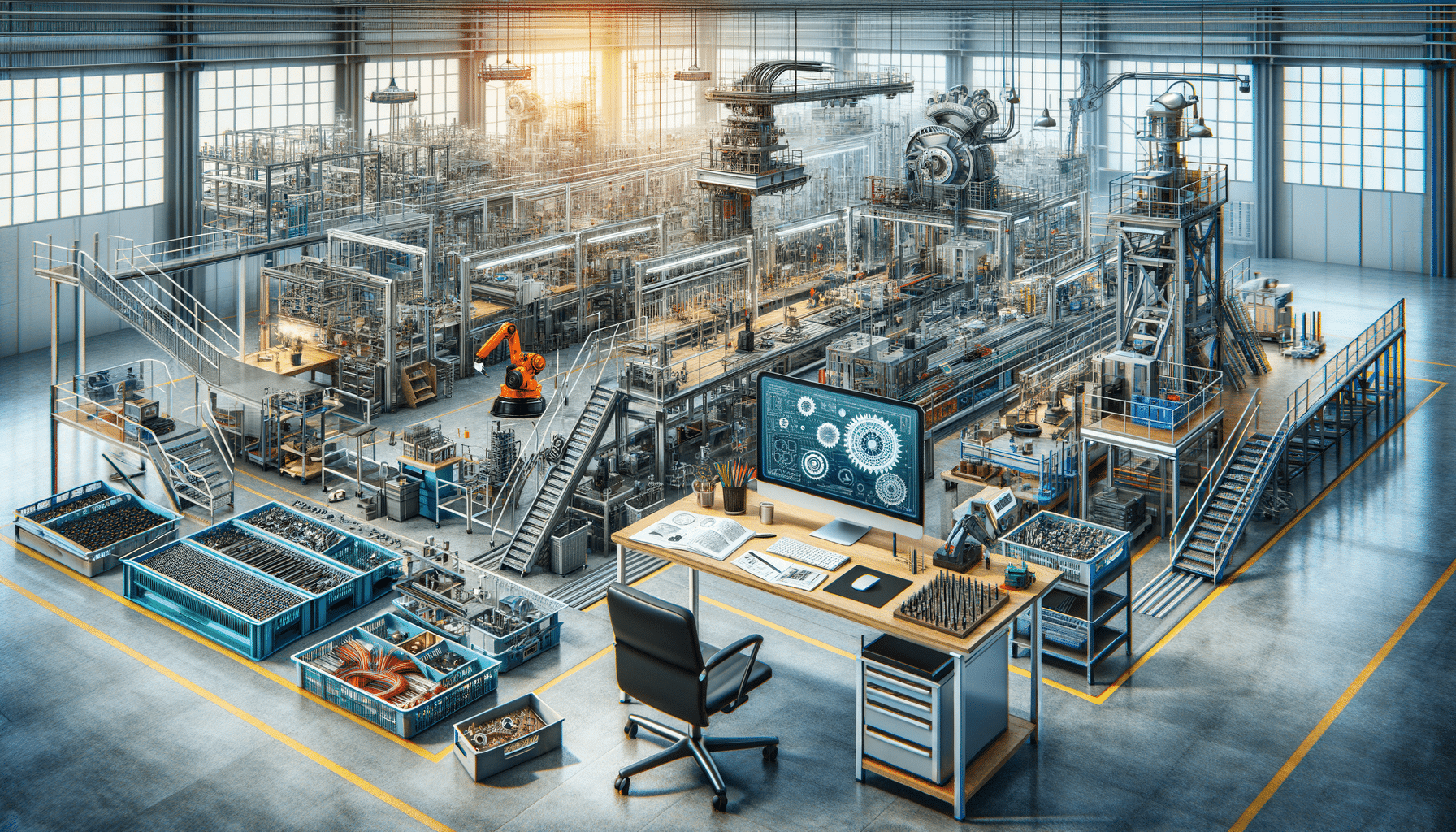

Industrial manufacturing is a cornerstone of economic growth in Washington, driving innovation and providing numerous job opportunities. As demand for skilled workers increases, training programs have become essential for those looking to enter or advance in this field. Industrial manufacturing training equips individuals with the knowledge and skills required to operate complex machinery, manage production processes, and ensure quality control. This training is not only about technical skills but also about understanding the broader context of manufacturing operations, including safety standards, environmental regulations, and the latest technological advancements.

Training programs are designed to cater to various levels of expertise, from entry-level positions to advanced roles. These programs often include hands-on experience, allowing trainees to apply theoretical knowledge in real-world settings. As the industry evolves, staying updated with new technologies and methodologies becomes crucial, making continuous learning a key component of a successful career in industrial manufacturing.

Key Components of Industrial Manufacturing Training

Industrial manufacturing training encompasses several critical components that ensure comprehensive learning. These components are designed to build a strong foundation and enhance specific skills required in the industry.

- Technical Skills: Training programs focus heavily on developing technical skills, including the operation of machinery, understanding production workflows, and implementing quality assurance practices.

- Safety and Compliance: Safety is paramount in manufacturing environments. Training includes extensive modules on workplace safety, compliance with industry regulations, and emergency response procedures.

- Technology Integration: With the advent of Industry 4.0, understanding and integrating new technologies such as automation, robotics, and data analytics into manufacturing processes is crucial.

- Problem-Solving and Critical Thinking: Trainees learn to analyze and resolve production issues, optimize processes, and improve efficiency through innovative solutions.

By focusing on these components, training programs prepare individuals to meet the challenges of modern manufacturing environments, making them valuable assets to employers.

Opportunities and Career Growth in Washington

Washington’s industrial manufacturing sector offers a plethora of opportunities for trained professionals. The state’s strategic location, coupled with its robust infrastructure, makes it a hub for manufacturing activities. With the right training, individuals can explore various career paths, from machine operators and production managers to quality control specialists and process engineers.

One of the significant advantages of pursuing a career in industrial manufacturing in Washington is the potential for career growth. Companies in the region are known for investing in employee development, offering pathways for advancement and specialization. Furthermore, the competitive salaries in this sector are an attractive aspect, often exceeding expectations for skilled workers.

For those interested in entrepreneurship, the manufacturing industry also presents opportunities to start small businesses, providing specialized services or products. As the industry continues to grow, the demand for innovative solutions and efficient processes creates a fertile ground for new ventures.

Overall, with the right training and a willingness to adapt to industry changes, individuals can build a rewarding and stable career in Washington’s industrial manufacturing sector.